It all started from a hostel room where Sudeep Sabat, COO, Mukunda Foods and Eshwar K Vishwa, CEO, Mukunda Foods would dream of building a McDonald’s of Indian foods just like many aspiring entrepreneurs. That's when they started with their first venture, a QSR, and their customers would love their Dosas and Idlis. It was going all well till they scaled up and opened few outlets. “We could not match the food consistency across the outlets, which affected our customer base. This was our encounter with the market reality of F&B business that scaling is tough, but maintaining consistency and controlling operational costs are tougher,” shared Vishwas by adding that the incident made the engineers in them awakened, and that’s when they started working on a solution to it. “Finally, we came up with World's first fully automatic Dosa-making machine, and we decided to be a catalyst in the making of McDonald’s of Indian Foods,” he pointed proudly. Read more about his story:

Overcoming the challenges faced

It starts with the basic question of the challenges faced by F&B business, then the research and development take around a year or a little more than that before we finally get these products in the market. For instance, be it a cloud kitchen & QSR, they struggle with perfect cooking of Rotis, Parathas, Kulchas; therefore, there is a need for a solution that cooks these items more efficiently and quickly. Our latest product E-Pan bridges this gap, and it comes with an intelligent system for puffing, requiring minimum human intervention. In addition to this, With F&B businesses back-ending their flatbreads, Patties, and Parathas into frozen food, E-Pan helps them serve these frozen items that taste like freshly cooked food items.

Driving the automation quotient

So far, Restaurants use to thrive on social gatherings, but pandemics changed how it works. As a result, we can see the shift from dine-in to delivery, and the customers seem to be happy with this change. However, the delivery model also comes with its own set of challenges like aggregators would hardly give you 10-15 mins for meal prep, which puts an additional load on your staff, and you might require hiring skilled staff. Maintaining food consistency also becomes another concern with a high dependency on human intervention. This is where Mukunda's automation solutions help them address these concerns and smoothen their operations.

We have automated 14+ processes that can help restaurants maintain consistency, reduce dependency on skilled labor and gain operational efficiency. Here are our four most celebrated products:

Wokie: A fully automated cooking station for Asian and Wok-based recipes.

Eco-Fryer: Automatic fryer for perfect crispiness and frying that also helps save oil and energy.

E-Pan: Makes wraps, Parathas, flatbreads effortlessly with its intelligent puffing system.

Dosamatic: Easy to operate machine that pulls of the absolute crispiness and flavors of a dosa.

Who are some of your clients? Are there any revenue-sharing fees or something?

We have clients from a different set of F&B businesses like Cloud Kitchen, QSR, Hotels, Corporates, etc., and to name some of them, we have Rebel Foods, JFL, Chayoos, Swiggy, Ola Foods, and ITC. Our standard revenue model is pretty simple, where every product has a fixed cost attached that the clients pay while purchasing the machine. However, while launching our latest product, i.e., Combi-Oven, we got a common suggestion from the market of having a rental model. This product tops the list of essentials for commercial kitchens, but the upfront CAPEX investment becomes a concern for QSRs and small business owners. Therefore, we have come up with a rental model that works well for the clients.

It is believed that with tech playing an important role, centralized data plays an important role in making business more automated. Why so? And, how are you helping with the same?

The centralized data and IOT help automations work at their best of capabilities and give decision-makers a lot more control over their businesses. At Mukunda, our machines are IOT enabled, so clients will have full control over setting up the recipes based on their Sops, and they can also modify it from the central location whenever they want. They also get to see a daily report like which are the highest selling food item all the locations, which are preferred in specific locations and these kinds of insights help them make decisions. To put it in simple words, the client will have control over wherever the machines are installed.

This helps them achieve consistency, and their staff can also multitask as the machines follow the sops anyway.

How have you made machines automated for cuisines? How much time did it take in research and development?

Our domestic kitchens have different cookware set for different kinds of cuisines as it largely impacts the final food. The same logic goes with commercial kitchens; most of the time, challenges faced by them are cuisine-specific. For example, tossing Chinese food might not sound like a tedious job, but it requires skilled labor, and the attrition rate is too high in the F&B services business. Wokie from Mukunda is a solution to these challenges, and it can cook any toss-based recipes as per the standard Sops. Similarly, Eco-Fryers solves the problem of under and over-frying fried items. Ideally, the research and development take around a year, including market validation and product trial at actual commercial kitchens.

Going with the trend

India took a comparatively little longer to adapt, whereas countries like Australia, Canada, and United States were more open. However, Indian Restaurants became more receptive to technological advancements in a post-Covid situation since there was a concern of skilled staff and labor because of the migration. In addition to this, hygiene and safety became a priority, and Kitchen automation solutions could easily bridge these gaps. To put it in context, Mukunda signed up three times of customers compared to FY 2018-2019. So, I would say kitchen automation emerged as a stronger player during the Pandemic in India and is expected to get stronger in the coming times.

What's your global presence? What's the expansion plan?

So far, we have helped automate 2000+kitchens across 22 countries, but we haven't made conscious efforts to penetrate the international market. There is a fairly decent demand for automated kitchen equipment for Asian Foods in Australia, Canada, United States, and the UK. There is also a demand for solutions that are more functionally and operationally efficient than aesthetically. So, with nine amazing products in our kitty, our focus will be to penetrate these markets as we are finalizing some global distribution partners.

With extensive experience in scaling Korean food brands across global markets — including the Middle East, Seung Hoon Lee (Sean Lee), Founder of Seoul Dak, has been instrumental in taking authentic Korean cuisine to international audiences. Now, he is channeling that expertise into building Seoul Dak as a global brand rooted in real Korean flavours, starting with India. In an exclusive conversation with Restaurant India, Lee speaks about the brand’s vision, expansion strategy, authenticity, and more. Excerpts:

What inspired you to start Seoul Dak, and why did you choose the Indian market?

When I first visited Mumbai in 2022, I noticed many restaurants claiming to serve Korean food. By my second visit, Korean menus and instant noodles were everywhere, yet the flavours felt far from authentic. That gap sparked the idea behind Seoul Dak.

India was clearly embracing Korean culture through music and dramas, but I felt consumers hadn’t yet experienced real Korean flavours. Fried chicken became our entry point because it’s universally loved and one of Korea’s most iconic dishes.

When did you launch the brand, and how was the initial response?

We launched our first store in January 2025 inside Food Square in Mumbai. The response was explosive from day one. Over the last 12 months, we’ve expanded to Bandra, opened two outlets in Pune and one in Bengaluru. It’s been a hectic but exciting journey.

As you expand, how do you cater to diverse Indian taste preferences?

Authenticity is non-negotiable for us. We don’t alter the DNA of Korean flavours, even though many suggest we should “Indianise” the menu. The only adjustment we’ve made is increasing the spice level slightly to match India’s higher heat tolerance — without changing the core flavour.

Instead of changing recipes, we adapt by carefully selecting menu items that Indian consumers can connect with. For example, seaweed is extremely popular in Korea, but it didn’t resonate strongly here, so we removed it.

What does the name Seoul Dak represent?

“Dak” means chicken in Korean, and Seoul is the capital of Korea. The name immediately signals that we are a Korean brand. Even if someone isn’t deeply familiar with Korean cuisine, seeing “Seoul” helps them connect the dots.

What differentiates Seoul Dak from other Korean brands in India?

Ingredients matter. Even if it’s the same chilli, Korean chilli tastes very different from Indian chilli. We import our sauces and spices directly from Korea and source only the chicken locally. That ensures authenticity at the core — and that’s where we stand apart.

Has the brand identity resonated with Indian consumers?

Yes, absolutely. Even people who haven’t tried us recognise us as a Korean brand. I’ve personally heard people say, “I’ve seen that Korean restaurant in Bandra — I want to try it.” That recognition itself is a strong sign.

How important is consistency while scaling a QSR brand?

Consistency is everything. We chose the QSR format to make Korean food affordable and accessible. We centralise sourcing in Mumbai, process ingredients at our Pune facility and control distribution internally. Extensive staff training ensures that the experience remains the same across cities.

What were some of the biggest operational challenges?

I wasn’t familiar with the Indian market, so everything — from real estate to hiring — was a learning curve. Finding managers who align with our culture was tough. Training is ongoing, but we are building a strong Seoul Dak culture that reflects what it means to be part of the brand.

How important is storytelling for the brand?

My primary job is to deliver real Korean flavours. But storytelling has become important to educate consumers, especially when many brands misrepresent what Korean food actually is. We want people to understand what authentic Korean flavours truly taste like.

How has consumer perception of Korean cuisine evolved in India?

Korean flavours are now everywhere — in malls and on quick-commerce platforms. Interestingly, many consumers are choosing imported Korean noodles over Indian-made “Korean-style” versions. That shows a growing demand for authenticity.

Who is your target audience, and what about pricing?

While many of our customers are young and socially active, our real target is all of India — from students to families, aunties to grandmas. Our pricing is consistent across cities to maintain clarity and accessibility.

Has K-drama and K-pop influenced this trend?

Absolutely. It’s a global K-culture movement. Through music, dramas and food, people experience what it’s like to be Korean — and food plays a big role in that.

What role will delivery and cloud kitchens play?

We haven’t started delivery yet. For now, we’re focused on dine-in to ensure quality and authenticity. We plan to launch delivery later this year once we’re confident that we can maintain the experience.

What are your expansion plans?

We aim to reach 25 outlets by the end of this year and 50 by next year. All outlets are company-owned and bootstrapped because maintaining authenticity is difficult in a franchise model.

Long term, we want to be present across India and are also exploring markets like Dubai and Saudi Arabia.

After earning his Hotel Management diploma from IHM Hyderabad, Kush Kapoor began his journey at the very grassroots of hospitality—as a room boy at The Trident Udaipur and Trident Cochin. It was here, on the hotel floors rather than in boardrooms, that he developed a deep understanding of service, discipline, and the finer nuances of luxury hospitality. Over the next 23 years, Kapoor steadily rose through the ranks, shaping his leadership style across some of India’s most iconic hotel brands, including The Oberoi Group, The Taj Group, and The Leela Group. Each role added to his perspective on operational excellence, brand building, and guest experience.

His entrepreneurial vision culminated in the launch of Roseate Hotels & Resorts in India—a brand that has since carved a niche in the country’s luxury hospitality landscape. Today, as CEO, Kapoor leads the group with a strong focus on innovation, expansion, employee engagement, and sustainability.

In an exclusive conversation with Restaurant India, Kapoor reflects on his remarkable journey from the hotel floor to the corner office, sharing insights into leadership, growth strategies, and the evolving future of luxury hospitality. Excerpts:

The Roseate is positioned as a niche luxury brand. How do you define “luxury” today?

Luxury means different things to different people. In hospitality, I believe luxury is about delivering genuine value to the guest. If you are able to provide meaningful returns on what a customer invests in you—whether through service, comfort, or experience that is true luxury.

What is your long-term vision for The Roseate Hotels & Resorts in India and globally?

From the beginning, we were clear that we did not want aggressive expansion. We prefer to remain a mid-sized luxury brand, growing steadily while maintaining exclusivity and uniqueness.

Currently, we own and operate eight five-star luxury hotels across India and the UK. We are in discussions to expand in Dubai and parts of Europe, adding 2-3 hotels annually. Beyond hotels, we are expanding into Ayurvedic spas outside hotel properties and launching experiential mithai boutiques. Every new venture undergoes extensive R&D to ensure long-term uniqueness. The Indian market today is mature and ready to invest in luxury experiences.

How do you balance luxury with changing guest expectations around value, sustainability, and personalisation?

Technology plays a major role but we design it according to our needs. Our proprietary apps and systems are exclusive to Roseate. We use AI-generated calls and structured feedback systems aligned with our brand standards.

Importantly, we do not view technology as a replacement for people. Instead, it is a tool that empowers our teams to spend more time engaging meaningfully with guests. By developing our own systems in-house, we remain agile and can quickly adapt to evolving guest expectations.

How do you evaluate new destinations before entering?

Location is always our first priority. We are currently exploring expansion in key metros like Mumbai and Bengaluru, as well as major pilgrimage destinations such as Ayodhya, Varanasi, and Tirupati. We are open to partnerships in these markets but only with the right collaborators who align with our brand philosophy.

How do you balance cost optimization by maintaining luxury standards and supporting employee welfare within your organisation?

We maintain costs at an optimal level without compromising guest satisfaction or employee well-being. In luxury hospitality, every detail from service to food quality must remain exceptional. For example, we allow employees to purchase groceries once a week from the same vendors who supply to our hotels. They receive premium-quality products at significantly lower prices, helping them save 30–40% monthly on groceries. This initiative supports employee welfare while maintaining supplier consistency.

Roseate has introduced innovative employee engagement initiatives. Could you elaborate?

Employee retention has been a priority. We ensure work-life balance, for example, female employees are not assigned late-night shifts. We provide 24x7 pick-and-drop facilities for employees living beyond a 20 km radius. Work hours are strictly monitored to ensure no one works beyond 9–10 hours a day. This is tracked digitally and considered during appraisals. Training is conducted online, supported by a mobile HRMS system. Feedback mechanisms ensure responses within 24 working hours.

We also conduct a monthly three-day ‘Happiness Program’ in collaboration with Art of Living for 25–30 employees at a time, focusing on emotional well-being.

What kind of leadership culture are you building within the organisation?

We foster an open culture—no personal cabins for senior management, and employees can approach leadership anytime. Our philosophy centers on the three E’s: Emotions, Experience, and Education, guiding both staff and guests in evolving hospitality standards.

What trends will shape India’s luxury hospitality sector over the next five years?

Experience and transparency will define the future. Today’s customers are well-travelled and informed. If they are paying for luxury, they expect more than standard service. Hotels must avoid taking customers for granted and should clearly communicate what they can and cannot offer. Transparency builds trust and long-term loyalty.

What advice would you give young professionals aspiring to build long-term careers in luxury hospitality?

This is a golden era for India’s hotel industry. Young professionals should focus on innovation, quality, and creativity. Success cannot be measured by a fixed benchmark. If you can improve even slightly from what you did yesterday, that itself is meaningful progress.

Actor Mona Singh rose to fame with her iconic television role in Jassi Jassi Koi Nahi and has since remained active across television and films. She was last seen in Anurag Singh’s Border 2 (January 2026), Aryan Khan’s directorial debut The Bads of Bollywood (November 2025), Laal Singh Chaddha and Munjya. In 2025, she ventured into hospitality with her Mumbai restaurant Kona Kona, and has now expanded the brand with a second outlet in Andheri.

In an exclusive interview with Vijetha Iyer, Mona Singh speaks about the new launch, expansion plans, the menu and more. Excerpts:

You’ve had a versatile career across TV, films, and OTT. What inspired you to step into the restaurant business with Kona Kona?

My idea was always simple; to feed people. I’ve always loved Indian food in all its diversity and wanted to celebrate it. Opening a restaurant or café had been on my mind for a long time, but the real moment came during a casual conversation with friends who asked if I’d be interested in doing it for real.That felt like the right time and opportunity to step into hospitality and learn along the way. Everything then fell into place organically from the name Kona Kona to the menu. The restaurant is located on a kona, or corner, and the food represents flavours from every kona of India.

Kona Kona is a celebration of food—a friendly neighbourhood bar, a familiar go-to spot where people can come together over nostalgia, music, and comforting meals. In hindsight, it feels like it was always meant to happen.

Kona Kona has a distinct vibe. How much of your personality and taste is reflected in the restaurant’s concept and menu?

We wanted the space to feel unmistakably Indian, yet familiar, easy, and welcoming. I’m deeply involved in curating the menu. Having travelled across the country while my father served in the army, food became my way of connecting with different regions. That journey shows up on the menu, which brings together flavours from across India—from Jhol Momos and Himachali Siddu to Punjab ki Chikar Chole, a dish especially close to my heart as it’s my mother’s recipe. We consciously included dishes that feel personal, making the menu a collection of memories rather than just a list of dishes.

Acting and entrepreneurship are both demanding. What has been the biggest challenge in balancing the two?

I’ve been clear about surrounding myself with the right people to handle the day-to-day operations, as I’m still learning the business side. My role is to support and promote the brand and enjoy the space with friends. When I’m shooting, I can’t be at Kona Kona every day, but I’m never disconnected. Most decisions are discussed and finalised over Zoom, which helps us stay aligned even when I’m not physically present.

Has being an actor helped you in running a restaurant, whether in branding, storytelling, or connecting with people?

My personality reflects in Kona Kona through both the décor and the menu. Being an actor has also helped with visibility and promotion—friends from the industry, including Farah Khan and Chef Sanjeev Kapoor, were happy to visit, shoot, and support the space. That kind of goodwill and storytelling has definitely helped Kona Kona connect with a wider audience.

Looking ahead, do you see yourself expanding Kona Kona further?

Yes, we’re already expanding—this is our second outlet, and the plan is to keep growing. We want to move beyond Mumbai and eventually take Kona Kona across India and globally through franchise outlets. On the acting front, I’m focused on reinventing myself, taking on new challenges, and staying relevant across films, OTT, and all mediums.

Mumbai has an incredibly competitive food scene. What sets Kona Kona apart?

I think it’s a mix of our service, staff, food, ambience, music, and drinks. Our duck logo reflects the fun concept—there’s a saying, “Drink like a duck.” We also host pop-ups featuring different regional cuisines, with guest chefs showcasing everything from Manipuri to Lucknowi dishes. These pop-ups help us celebrate and promote the diverse flavours of India, even from smaller regions.

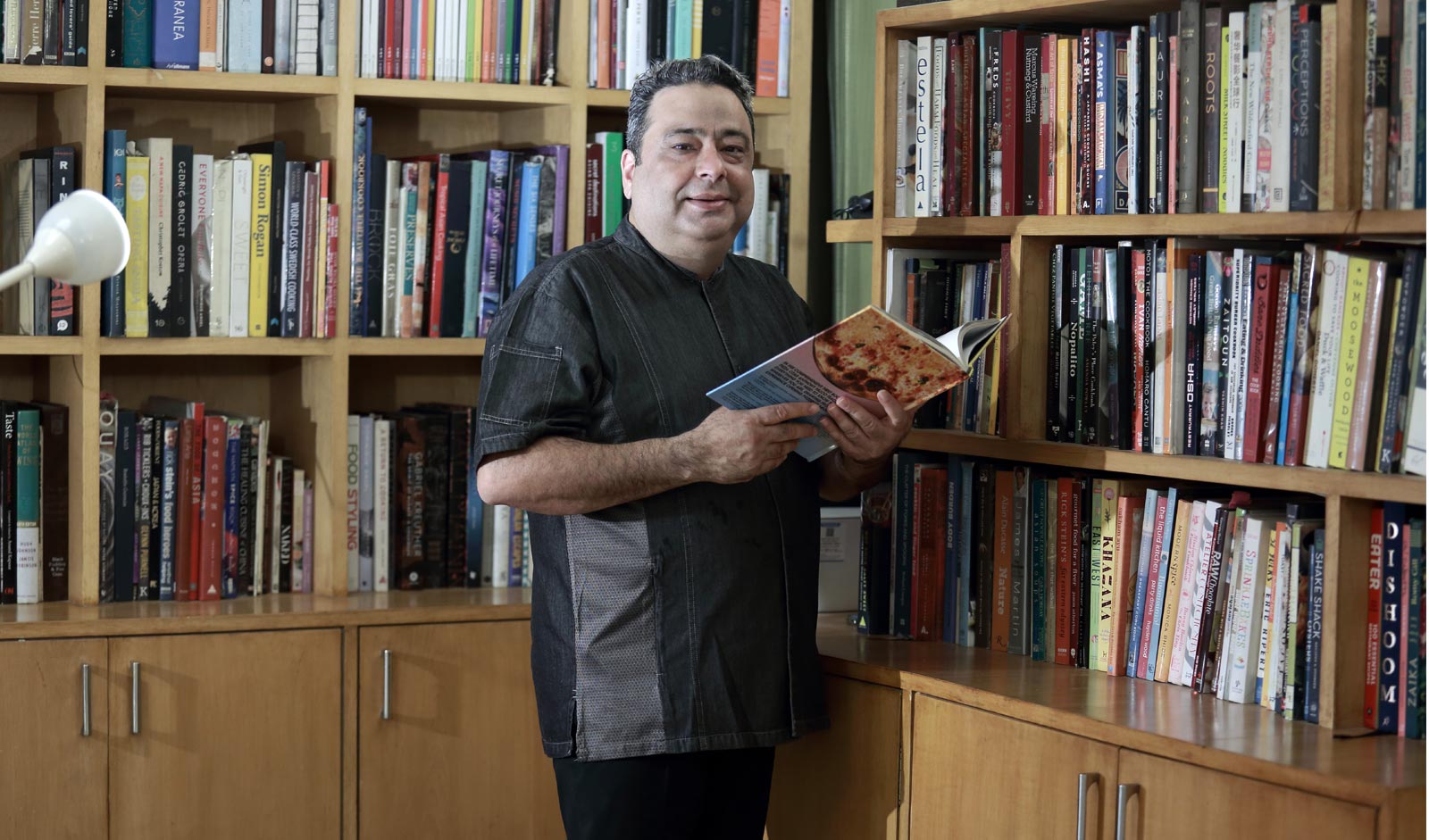

With over 24 years in the hospitality industry, Chef Deepak Dandge is the Director of Culinary at Pullman Chennai. He is a graduate of the Institute of Hotel Management (IHM) and has worked with several leading hospitality brands, including Sofitel BKC, Marriott, Taj, Westin, amongst others.

In an exclusive interview with Restaurant India, he talks about his journey, culinary experiences and much more. Excerpts:

Culinary philosophy

Chef Deepak Dandge’s culinary philosophy blends tradition with innovation. Whether learning from highway dhabas near Mumbai during his student days or exploring the science of food through gastronomy books in his spare time, Chef Dandge's approach is grounded in curiosity and authenticity.

“I have worked in different locations till now. But every location has different taste palate and the cuisine they prefer may differ as well. For Eg: In Chennai, every place has their own style of making sambhars and chutneys, the spice level and the ingredients they use differ as well. But if we compare the food we get in South vs North, the taste is completely different, the spices are different,” he said.

Involvement of 5 senses

The guest experience starts when a guest enters the hotel/ restaurant. What they see, smell, eat, hear and touch, all of them have to be perfectly aligned.

“We have to ensure that the seating arrangement, menu ordering, plating is perfectly taken care of. Food should be eye-catchy and ambience should please them. Guests should be welcomed with warmth, and their preferences have to be taken in consideration with suggestion of more options from the server/chef’s end,” added Chef Dandge.

Training/staffing

Training, staffing and retention are one of the major challenges in the industry. If there is a room to grow, then staff stays, otherwise they tend to leave for more growth opportunities.

“Growth eventually slows, so people may switch roles to grow faster. It’s important to talk to your staff, understand what they want, and recognize the opportunities they’re getting. The right knowledge helps you grow in life,” said Chef Dandge.

Menu development

Innovation plays a major role, and guests need consistency in what they eat. While catering to various cuisines, authenticity and consistency matters.

“The most important thing is selection of your team as I believe that they make it or break it. You need to train them about your expectations,” he added by pointing that for menu development, what helps for longer run is storytelling and understanding about what to focus and what not to.

Optimizing food-costs

If you are wisely using any product, then the food cost can be controlled. But it should not hamper the quality you serve to the guests. “We have ‘Control Policy of Wastage’ and we have a machine which we use to see how much wastage is there. This helps in identifying the waste and to reduce them. It is chef’s duty to control the wastage and how he guides his staff to curb them,” mentioned Chef Dandge.

One need to understand the cooking style for buffets, kitchen and for various occasions. If you can control the costs, then you can elevate the experience in buffets as well.

Preparing team for high-volume events

“We have different kitchens for restaurant and banqueting. We also get chefs from outside to cater to bigger events. The team should know the quality of food you serve,” he added as for him preparation is a must for any event.

Rise of Regional cuisine

Regional cuisine is the key. It’s all about how you cook the South-Indian food and how you cater them. For Eg: Biryanis in south is pretty different from what you consume in other locations. The spice-level, ingredient differs a lot. Guests are curious to know about the authenticity of the dish and want to learn about the story behind it.

Dining Trends

• Focusing on guest preferences is important

• Innovation in Chaat items

• Health cuisine, buffets are trending

• Zero-waste, in-house sourcing, options in small portions menu are more.

Started by Zaid Haroon Sait in March 2018, Zed The Baker was born out of the idea of creating a premium artisan bakery that delivers high-quality, preservative-free baked goods to Indian consumers. What began as a single boutique bakery-café in Bengaluru quickly resonated with customers, paving the way for steady expansion across the city.

This success was followed by the launch of Le Melt last year, a brand that celebrates indulgence and innovation, and the upcoming debut of Le Chocolat, set to open in Bengaluru later this year. Today, under the umbrella of Advanced Baking Concepts Pvt. Ltd., Zaid leads a growing portfolio of brands, with Zed The Baker expanding into a chain of over 14 outlets in Bengaluru, redefining the city’s artisan baking landscape. Excerpts:

What is the core concept behind Zed The Baker?

The brand is built on authenticity, from-scratch baking. We focus on craftsmanship, consistency, and high-quality ingredients—areas we felt were missing in the premium bakery space. By combining artisanal techniques with tech-driven processes, we’ve created a brand that delivers freshness and quality at scale.The key difference lies in our approach. We use better ingredients, follow strong SOPs, and rely on technique rather than shortcuts. While traditional bakeries focus on volume, we focus on clean labels, slow fermentations, and natural flavours.

Was scalability part of the plan from the beginning?

Yes, absolutely. The concept was designed to scale from day one. We operate with a central kitchen that supports multiple outlets. Along with retail cafés and café-restaurants, we also work in the B2B space, supplying premium hotels and offering catering services.

Why did you decide to reduce the menu size so significantly?

Maintaining quality and consistency across a very large menu is challenging. We reduced our offerings from 384 SKUs in 2018 to 87 today, with a goal of reaching 40 SKUs by April 2026. A focused menu allows us to perfect best-sellers and scale more efficiently.

What kind of experience do your cafés offer?

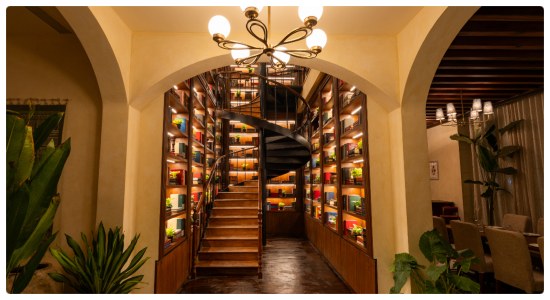

Zed The Baker operates as a European-style café. Each outlet offers an experiential dining journey inspired by different parts of Europe. Innovation is central to our identity, and once the menu reaches its optimal size, we plan to introduce monthly special menus curated with international chefs. For us creativity must have a purpose. Every idea should enhance flavour and improve the customer experience. We’re a product-oriented business, so creativity is meaningful only when it adds value, especially in dine-in formats.

How have consumer preferences influenced the brand?

Indian consumers today are well-travelled and increasingly quality-conscious. They value experience as much as the product. Our philosophy is simple—let the ingredients and technique speak for themselves. Our pricing ranges from ₹80 to ₹300, making premium baking accessible to a wide audience.

How do you engage with customers and gather feedback?

We’re a tech-driven company with a loyalty program called Relo. We’re also launching a one-year membership priced under ₹2,000. Members will get exclusive access to tastings of new products, and their feedback helps us decide what stays on the menu and how it evolves.

What challenges has the brand faced?

Skilled labour is one of the biggest challenges in the industry. We address this through detailed SOPs and semi-automation. Another challenge was maintaining consistency across a large menu, which led to our decision to streamline SKUs.

What’s your expansion plans?

We plan to open 50 Zed The Baker outlets by 2027, along with 10 Le Melt ice cream cafés and five Le Chocolat outlets. We’re also exploring international expansion in London, Saudi Arabia, and Dubai, and will open 10 more outlets in Bengaluru by the end of this year.

Chef and food influencer Kriti Dhiman who was last seen in MasterChef India Season 8, has recently opened her restaurant ‘Namma’ a modern celebration of the iconic Benne Dosa in Chandigarh. What began as a personal passion has today evolved into Namma, a South Indian restaurant rooted in comfort, authenticity and family. In an exclusive conversation with RestaurantIndia, Kriti Dhiman, Founder of Namma talks about her journey, new restaurant and much more.

The Philosophy: Simple Food, Deep Comfort

The cooking philosophy is simplicity. Food does not need unnecessary drama, it needs honesty. At Namma, the idea is straightforward: the food should speak for itself, feel comforting, and taste unmistakably good.

“The name Namma, meaning “ours,” reflects the deeply personal nature of the journey,” shared Dhiman whose family has been involved at every stage of building the brand, making the restaurant a shared dream rather than a solo pursuit. “Every dish aims to recreate the warmth of ‘ghar ka khaana’ food that comforts the gut as much as the heart. We want people to come back again by giving good quality food and by maintaining consistency,” she added.

Focusing on the menu, she added, “The menu focuses primarily on South Indian cuisine, with a special emphasis on Benne Dosas.” She also added that the team is constantly exploring ways to strike a better balance between indulgence and health, without compromising taste.

Rethinking Authenticity

Authenticity is not rigid. South Indian food itself changes every few kilometers in each state, region and household as each one of them have their own version. Authenticity, therefore, is less about fixed recipes and more about the comfort food provides.

“If the food brings the same warmth and satisfaction, small changes in technique or flavour are acceptable and that belief allows room for evolution while staying emotionally rooted in tradition,” mentioned Dhiman who launched Namma, seeing a clear gap in markets like Chandigarh, Delhi.

Balancing Flavours, Textures and Presentation

Presentation at Namma remains deliberately minimal. “Textures should feel right with every bite and flavours should complement rather than compete and ingredients must be handled with care,” she pointed.

Menu Planning, Sourcing and Consistency

Running a small restaurant has taught the power of focus. “Instead of an overwhelming menu, Namma keep things tight and intentional. A shorter menu ensures better quality control and less confusion for guests.All masalas are prepared in-house.

“Ingredients are sourced locally wherever possible, while certain essentials are brought in from the South to maintain authenticity. The chef personally monitors quality, fully aware that inconsistency is one of the biggest reasons restaurants fail,” Dhiman mentioned.

Three key trends

• Sustainability

• Small plates

• Conscious reduction of food waste

Wearing Two Hats: Chef and Influencer

Balancing life as a restaurateur and a chef-influencer comes with its own learning curve. While in the online platform, the audience is largely young students and first-time cooks who are curious about recipes and techniques. At the restaurant, the demographic spans all age groups. Dhiman mentioned that real-world guest interaction is irreplaceable. Conversations with diners help fine-tune dishes and menus in ways social media never can.

The Challenges

The biggest challenge in opening Namma has been building the right team. “Hiring, training and trusting people required the chef to unlearn habits and let go of complete control. Another major shift was moving from a health-focused approach to fully embracing a cuisine known for indulgence,” shared Dhiman.

Signature Creations with Familiar Roots

Innovation at Namma often begins with familiarity. Two standout dishes reflect this approach:

Garlic Dosa – Inspired by the universal love for garlic naan, this dosa bridges comfort across cuisines while retaining its South Indian soul.

Mushroom Truffle Dosa – Created out of a personal love for mushrooms, this dish brings depth, aroma and indulgence together without overpowering the dosa itself.

Advise for aspiring chef entrepreneurs

To aspiring chefs dreaming of opening their own restaurant, the advice is clear: start small, keep your menu focused, never compromise on quality, be ready to unlearn and adapt.

Dushyant Singh’s entry into the food and beverage world was neither planned nor guided by formal hospitality training. He entered in hospitality back in 2018 and today he runs four brands with 8 outlets that includes OTH, Rustic, Llama and Coffee Sutra in Jaipur.

“I’m not a trained staff, nor have I done hotel management,” he said. What he dreamt was a doing something meaningful in his own city. Fifteen years ago, this ambition led him to start his journey in F&B.

“In 2013, after running a joint venture with a friend, I launched my first independent restaurant: OTH, an all-day American diner that became one of Jaipur’s most iconic dining destinations,” he remembered as it introduced Jaipur to its very first standalone breakfast culture. Until then, breakfast was a five-star affair. From that first milestone, Singh expanded with a mix of cuisines and concepts: Excerpts:

The Birth of Coffee Sutra: A 360-Degree Coffee Company

It was during his global culinary explorations that he realized coffee was evolving into a lifestyle product worldwide not just a beverage. Although his restaurants served coffee, none of them were coffee-first concepts. That gap fuelled the creation of Coffee Sutra, envisioned as a full-circle coffee ecosystem with in-house coffee roaster, B2B and D2C coffee bean supply and hotel consultancy related to coffee operations. “We pick our beans directly from farms, roast them, train our baristas, and run our cafés. It’s a 360-degree model,” he shared smiling.

Why Jaipur?

“I’m a Jaipurite. And there’s no city as charming as Jaipur,” he shared as he believed Jaipur is a rare blend of heritage, modern aspiration, and well-travelled consumers. With lower rentals yet similar business potential compared to metros, Jaipur offers the perfect ground for experimentation and growth. When Coffee Sutra was launched, Jaipur was predominantly a tea-consuming city. But Singh witnessed firsthand how India’s palate was shifting.Tier 2 cities, especially, began embracing coffee as more than a drink, it became a social catalyst. From corporate meetings to college hangouts, coffee now bridged the gap between work, leisure and community moments.“Coffee is a reason for people to come out and connect,” he added.

Dine-in Over Delivery

While many brands chase delivery revenues, Singh shared, “I believe in creating experiences, and experiences cannot be created in delivery.”

Across his brands, 80% of business comes from dine-in, and he plans to keep it that way. Delivery is available, but never the priority.

Customer at the Centre

Over a decade, Singh’s restaurants have built a loyal community what he calls a tribe. These are customers who trust his food, hospitality, and brand ethos.“When we launch a new concept, our tribe is already waiting. This deep-rooted trust fuels every expansion and experiment,” he proudly mentioned.

What Sets Coffee Sutra Apart

Singh acknowledges that many brands serve great coffee. But Coffee Sutra differentiates itself through farm-level sourcing, in-house roasting, deep training and education for baristas, homemade desserts created to pair with coffee and warm, inclusive community-driven space. “We make sure we know exactly what we’re serving. The customer today is very educated,” he said. Every year, Singh’s team travels to Karnataka during the harvest season to inspect farms personally.

“Everything begins at the farm,” he emphasized. From picking the right beans to roasting and barista training, authenticity is a step-by-step commitment.

Expansion Plans

With Jaipur largely saturated, Singh is ready for the next chapter. “We will be opening Coffee Sutra café in Delhi (early next year). We are also exploring markets like Udaipur, Jodhpur, Ahmedabad, and beyond. Tier 1 is saturated. Tier 2 is booming,” he commented.

Narayan Poojari’s story didn’t begin with a business plan or an investor deck. It began with a small kitchen, a big dream, and a simple promise to feed his customers with love, honesty, warmth, and care. That was the entire business model. “One day, a customer walked up to me and said, “Why don’t you start pav bhaji? I want to eat it here. I smiled and said, let’s do it,” shared Poojari who has created a legacy with Shiv Sagar ruling hearts of Mumbaikars and Indians for its lip-smacking pav bhaji.

“I was running an ice cream parlour then, but I had spent 13 years working in canteens and hotels. I knew pav bhaji. I knew flavours. And I knew customers,” he shared as he worked on the dish, experimented, and worked day and night until he perfected it. “That pav bhaji counter changed the direction of my life. From there came South Indian, Mexican, North Indian, Italian, each cuisine opening a new door,” he smiled.

There are questions we ask the world, and then there are questions we ask ourselves.

“For me, the most important one has always been: How do you scale a brand without losing its soul?,” he shared.

From a Small Shop to a Big Vision

Poojari started his dream project at a small shop in 1999. A year later, he knew it was time to scale. “My mentor and partner, Mr. Bhagubhai Patel, stood by me, and together we opened our second outlet—right opposite The Dream Restaurant at Churchgate,” he proudly shared as he is now thinking to take the brand on the global stage.

For him, this business was about manifestation, consistency, and a bit of stubbornness. As a 13-year-old working in a canteen and attending night school, he would walk past that restaurant every night, whispering to himself about opening one like it someday.

Today, Shiv Sagar Group has evolved into multiple brands across multiple cities. Every concept is different, but the heart is the same. Indian hospitality- the guests.

Learning from Each Concepts

Every brand has its own journey, its own personality, its own lessons. “I have learned something or the other from each brand. And every concept has a completely different journey. It comes with its own thinking,” he shared as Shiv Sagar taught him discipline, recipe, and identity. Mahesh Lunch Home, where he is one of the partners, taught him to respect the sea—its freshness, its tradition. At Butterfly High, built together with his daughters Nikita and Ankita, taught him the joy of building as a family and of course, the newest baby, Kyma, the café-and-bar concept, taught him how the next generation thinks.

“We never chased numbers. We chased experiences as scaling, for me, is not a race. It is like cooking a biryani—slow flame, patience, and soul,” he smiled as he took Kyma and Butterfly to other markets like Hyderabad where both the daughters spent their time at the college.

The Real Secret of Scaling

Young entrepreneurs often ask: “How do we scale fast?,” he laughed by adding that he always tell them, scaling is easy, maintaining the scale is the real challenge. Every single day, the same warmth, the same taste, the same discipline—that is the real test.

People think consistency means control. But consistency doesn’t come from control. Consistency comes from care. And part of care is hygiene. “I tell my team to keep the place clean as if your family is coming for a feast.” But at the heart of it all a restaurant’s real product is not food. It is people. “Our chefs, our managers, our servers are the heartbeat of the brand. Guests might forget the dish they ate. But they will never forget how they made them feel,” he mentioned.

A long-Lived Legacy

After 35 years in this industry, I want to share four truths- Consistency is more important than creativity, don’t chase trends as trends fade but trust remains and never scale a problem—fix it first. Always, treat staff like family, but don’t turn the business into family drama. And, the biggest secret ingredient is presence as the brand grows based on what the owner sees on the floor and in the kitchen. “And our mission is simple to take Indian flavours and Indian hospitality across the world. We don’t want to export only food. We want to export Indian warmth. Our aim is to build a legacy of taste, tradition, and heart—one that travels across continents,” he concluded proudly.

For Chef Nikhil Nagpal, the story of taste began long before he donned his first chef’s coat. Growing up in an army family, his father’s postings across the length and breadth of India became an education in geography, culture — and most importantly — flavour. “Travelling around the country helped me train my taste buds to admire varied cuisines and flavours,” he recalls. “The disciplined lifestyle instilled punctuality, perseverance, and the ability to handle pressure with calm and composure.”

Where Rhythm Meets Cuisine

Avartana is a rhythm, iteration, mysticism. For Nagpal, it’s more than a name; it’s the philosophy behind every plate. “Each dish at Avartana is unique,” he explains. “The flow of dishes across the menu is designed like a symphony — an interplay of flavours, textures, and playful elements that create a seamless multi-course experience.” Each course is deliberate yet dynamic, much like the recurring cycles of music the name evokes — every repetition revealing a new nuance.

Innovation Anchored in Tradition

In a culinary era obsessed with novelty, Avartana stands apart by reimagining, not reinventing, tradition. Nagpal’s creative process begins not with imported truffles or liquid nitrogen, but with the local soil. “The ethos of Avartana has always been to keep the flavours and ingredients rooted to the southern Indian peninsula,” he says. “The selection of regional ingredients is the key first step in creating any dish.”

What follows is the transformation — traditional tastes elevated through international techniques, refined plating, and inventive textures.

Balancing Indulgence and Intention

In an age where diners seek both satisfaction and sensibility, Avartana’s multi-course menus are engineered for precision — portion, cost, and conscience. “Over the years, calculated estimates combined with intelligent culinary insights have helped us balance costs, guest expectations, and food waste,” says Nagpal.

Sourcing the Soul of the South

Avartana’s commitment to authenticity runs so deep that even basic ingredients like tamarind or pepper are sometimes transported to other Avartana outlets to maintain consistency. “Each ingredient is carefully sourced from trusted and reputed partners who undergo stringent checks,” Nagpal explains. “Once approved, that quality is maintained through the year for consistency.”

Sustainability: Beyond the Kitchen

At Avartana, sustainability is not a buzzword — it’s a business model. From intelligent water and energy management to waste segregation and local sourcing, ITC Hotels’ green philosophy shapes every decision. “Seasonality and regional biodiversity play a huge role,” Nagpal affirms. “We ensure efficient use of water and energy, minimal food waste, and support for local ecosystems — all of which align with ITC’s broader sustainability commitments.”

The Tightrope of Innovation

For an award-winning chef, the challenge is constant: how far can you push creativity without losing cultural authenticity? “The menus stay grounded to Avartana’s initial ethos — rooted in South Indian ingredients and flavours, yet presented in a modern avatar using global techniques,” he says and that’s why an Avartana experience feels futuristic without being foreign. The innovation is in the details — in a familiar flavour presented with unexpected elegance.

Scaling a Standard of Excellence

With Avartana expanding beyond Chennai, maintaining consistency is both art and strategy. Nagpal reveals that the process begins with people. “Every new Avartana team trains extensively at Chennai before opening elsewhere,” he says. “Detailed checks and balances ensure uniformity in cuisine and service. Even the décor — colours and design elements inspired by the region — maintains a familiar rhythm across cities.”

A Universal Palate

From Chennai to France, Nagpal has noticed one reassuring truth: good flavour transcends borders. “Today’s diners are well-travelled and open-minded,” he notes. “The food at Avartana is universal — relatable to locals and revelatory to international guests.”

Culinary Consciousness and Future Dreams

Health-conscious dining is another frontier Avartana is already addressing. “Our menus display dietary indicators with approximate calorie values, helping guests make informed choices,” Nagpal says. And what lies ahead for him personally? His answer is grounded and characteristic: “Avartana is about consistent efforts — the hero has always been the food and will always remain.” As for inspiration, it comes from everywhere — books, travel, art — but most of all, from the collective energy of his team. “We share ideas and inspirations constantly. That collaboration keeps creativity alive.”

In Sanskrit, Avartana means repetition — not redundancy, but refinement. For Chef Nikhil Nagpal, every service, every dish, every day is another iteration in pursuit of perfection. The rhythm continues — disciplined, inspired, and deeply, deliciously Indian.

From its modest beginning, Hatti Kaapi has expanded into a 110-outlet network across India and overseas, including its first international store in London. The timing aligns with a broader consumer shift: India’s domestic coffee consumption touched approximately 91,000 tonnes in 2023, and the café market, valued at USD 380.8 million in 2024, continues to grow at double-digit rates. “When we opened in Bengaluru’s Gandhi Bazaar in 2009, it was a 30-square-foot shop serving 3,000 cups a day,” recalled US Mahender, Founder, Director and CEO of Hatti Kaapi. “That little store propelled us to scale, and we didn’t look back.”

Sixteen years later, the South Indian filter coffee, has become a global talking point. And one of the brands most responsible for taking filter coffee into the mainstream café market. “For Hatti Kaapi, the timing couldn’t be better,” Mahender shared. Excerpts:

How it Began

Mahender credits his coffee instincts to his roots. “We come from Hassan, a coffee-growing region in Karnataka, and coffee is in our DNA,” he said. He and co-founder ML Gowdaji hail from families deeply tied to the Western Ghats plantation belt, like Coorg, Chikkamagaluru, and Hassan, regions that produce nearly 90 per cent of India’s coffee.

After years spent trading coffee, Mahender felt the need to build something of his own and for his late VG Siddhartha, the visionary behind Café Coffee Day was the inspiration. “He brought change to the Indian coffee industry. But Café Coffee Day focused on the western version of coffee. I grew up with filter coffee. So, we thought, let us offer something affordable and true to our palate,” he added.

That decision to make an authentic, milk-based South Indian filter coffee scalable shaped the brand.

Hatti Kaapi’s Growth Story

The next turning point came when Bengaluru Airport offered them a space. The store became a landmark. Today, Hatti Kaapi brews 2,000-2,500 cups a day at the Bengaluru airport alone. With Kempegowda Airport crossing 31.9 million passengers in FY23, this strategic placement amplified brand visibility exponentially. The airport model was soon replicated in Chennai, Hyderabad, Kolkata, Delhi, and Mumbai. Hatti Kaapi intentionally adopted a multi-touchpoint model, ensuring consumers encounter the brand across daily routines at airports, IT parks, malls, hospitals, hotels, and corporate events. While the brand stays loyal to filter coffee as its identity, Hatti Kaapi has expanded its café format.

“We’ve learned from global formats: while Starbucks sells an Americano, we focus on offering the best Indian coffee experience. We use quality machines and techniques, but the heart of our menu is true Indian filter coffee,” he pointed.

With growing demand, the brand’s model has also evolved its food menu, including mini idlis, Maddur vadas, rice rotis, upmas, croissants, vada pavs, and more. This positioning resonates in cosmopolitan cities where consumers expect native flavours alongside café culture. In line with this growth, the brand is also expanding into major metro markets, with new stores opening soon in Delhi, Chandigarh, Mumbai, Pune, and Hyderabad.

Rising Coffee Demand

India may be a traditionally tea-dominant country, but the coffee wave is rising, particularly among Gen Z and millennials.

“Earlier, coffee was a luxury. Now it’s a statement,” said Mahender, adding, “Today’s generation prefers coffee destinations to work from Café as the new workspace.” South Indian filter coffee recently secured the No. 2 position on TasteAtlas’ list of the ‘Top 38 Coffees in the World’, an acknowledgment that mirrors the rising popularity of India’s homegrown brew.

Global supply disruptions in Brazil and Vietnam have raised prices internationally, indirectly boosting Indian growers, who are now earning their best rates in recent years. Meanwhile, India’s annual coffee exports continue to stay strong between USD 1–1.2 billion.

“Looking ahead five years, every year is exciting. If domestic consumption rises from 40% to even 60%, it will be a great win,” Mahender mentioned for whom the next goal is to expand its presence into Tier-2 and 3 cities across India. “We want to move into tier-three towns and villages, put up small touch shops, give people a job or a franchise. They deserve a quality cup of coffee, too,” Mahender pointed.

Growing Global Presence

Hatti Kaapi already brews in London, and upcoming locations include Amsterdam, the United States, Dubai, and other parts of Europe. “The brand of Karnataka started from serving Rs 5 filter coffee at 5 AM, and now we have touchpoints across cities and countries. It’s a proud moment for us,” Mahender proudly shared by adding that he believe Indian coffee has a unique flavour that isn’t always claimed on the global stage, even though many international brands buy Indian beans.

"The time has come to say Indian coffee is among the best. We’re seeing international interest, brands coming to India and opening stores here, which shows strong potential for coffee. “Our mission is to offer true Indian filter coffee, everywhere,” he asserted.

In an exclusive interview, celebrated chef Manish Mehrotra of MMCA challenges culinary labels, urging a shift in perspective—from ‘Modern Indian Food’ to the authentic, evolving cuisine of modern India, focusing on trends, his plans and expert advice to fellow chefs…excerpts:

After over a decade shaping Indian Accent and championing Indian cuisine globally, what inspired you to start fresh with MMCA — and what’s the core idea behind it?

I've been part of the hospitality industry for almost 30 years now. I joined hotel management school in 1993, graduated in 1996, and have been working ever since. After three decades immersed in this world — creating, learning, gaining, and yes, losing along the way — I felt it was time to pause. I needed a break, a moment to step back and reflect. Thirty years is a significant stretch, and I had reached a stage in life where I needed to reassess what came next. With my daughter, off to pursue her own paths, it felt like the right time to stop, breathe, and consider what truly excited me now.

That break eventually led to MMCA. It’s not just another restaurant — it’s a more personal, layered journey into culinary expression, experience, and community. It's a space that reflects where I am today, creatively and personally.

What’s the vision behind MMCA, and how does it go beyond just being a restaurant venture?

MMCA is an F&B company I founded to bring multiple concepts to life — starting with restaurants. I'm currently developing four key formats: a fine-casual concept, a high-end fine dining space, a Thai cuisine-focused restaurant, and a vibrant chaat-inspired concept. Alongside these, I plan to expand into events and catering. But MMCA is more than just food concepts — it’s also about building people. Over the years, I’ve worked with many chefs who’ve gone on to achieve great things, and I want to give back through a mentorship program. It’s not an academy — at least not yet — but a hands-on, on-the-job training initiative aimed at nurturing the next generation of chefs and F&B professionals. That’s the heart of MMCA: creating spaces, experiences, and future leaders in the industry.

How have you seen Indian cuisine evolve over the years, and what role do you feel today’s generation of chefs — including those you’ve mentored — are playing in that journey?

I consider myself fortunate to have worked with many talented young chefs over the years — including people like Himanshu Saini. While I may have been a small part of their early journey, their success is entirely their own. It’s their vision, dedication, attitude, and sacrifices that have taken them where they are today. I was just a stepping stone — the rest is all their hard work.

It’s incredibly rewarding to see so many of these chefs making a mark globally, and that’s what motivates me to continue mentoring. I want to help shape more such professionals — not through a formal academy, but through real-world, on-the-job mentorship. That’s how true learning in this industry happens. As for Indian cuisine, it has come a long way and is finally receiving the global recognition it deserves. Chefs like Himanshu, Gagan, and many others around the world are presenting a new narrative — one that reflects the India of today. But here's something I feel strongly about: we should stop calling it “modern Indian” or “progressive Indian” cuisine. India has already progressed. Our cuisine has evolved. What we’re seeing now is simply the food of modern India — not a version in transition, but a confident, contemporary expression of who we are today.

When you started MMCA, was there anything you consciously chose to leave behind from your Indian Accent journey?

I wouldn’t say I left anything behind. Indian Accent was a defining chapter — I helped build it, worked with some incredible people, and grew immensely through that journey. Those years taught me a lot.

With MMCA, it isn’t about moving away from the past, but about creating something new. I have a wider canvas to experiment and express — to shape things differently, both in spirit and in approach. It’s a fresh chapter, but every learning from before continues to guide me.

What are five dining trends you believe will redefine how we experience restaurants in the coming years?

1. Experience Starts Before Arrival – Dining isn’t just about food anymore. If guests battle traffic or feel stressed before even reaching, the experience is already compromised. Accessibility and overall ease matter.

2. Relaxed Fine Dining – The new wave of fine dining is elegant but not intimidating. It’s about comfort, not stiffness. People want sophistication without feeling like they’re in a rulebook.

3. Effortless Hospitality – Service should feel intuitive, not performative. Guests appreciate warmth and attentiveness over formality.

4. Smart Casual Over Dress Codes – Today’s diners are aware. We no longer need to enforce rigid dress codes — most people know how to present themselves. When needed, we can always guide politely.

5. Holistic Design – Ambience, acoustics, seating, lighting — everything contributes to how a space makes you feel. The trend is toward creating environments that are both beautiful and calming.

In short, the future of dining is less about rules and more about thoughtful, human-centric experiences.

What’s your advice to young chefs entering the industry today?

I’ve said this from the beginning — hard work is a given in any field, but in this industry, it’s a different kind of hard work. It’s not just mental, it’s physical too. You’ll find yourself doing tasks you may not expect, sometimes even things a helper might do. And that’s okay. Dignity of labour is key. Nothing is beneath you in a kitchen. If you embrace every part of the job with humility and joy, you’ll grow — not just as a chef, but as a professional and a person.

Dishant Pritamani is a restaurateur driven by instinct and purpose, not convention. He founded The Daily Bar & Kitchen in Mumbai in 2013, creating a space that blurred the line between neighbourhood bar and cultural hub. Since then, he’s built a portfolio of distinct, experience-led venues from The Daily All Day and Tsuki in Pune to The Second House and Café Lento in Goa, each rooted in creativity, community, and conscious design. He plans to open Café Lento in Mumbai and Pune.

In an exclusive interview with RestaurantIndia, Dishant Pritamani, Founder of Luna Hospitality talks about his journey, AI-based restaurant, customer loyalty, sustainability and much more. Excerpts:

Handling Multi-Brand Venture

I believe work should bring joy and you can’t fake passion,” said Pritamani. “Each brand I’ve created reflects who I was at that point in my life. The goal is to stay authentic to myself and to the guests.”

When launching a new restaurant, he immerses himself in the process by spending over a year on-site to understand operations, team dynamics, and customer expectations. “I work alongside my team to ensure everything runs smoothly. Once they have been part of the journey from day one, they know how to carry it forward.”

While his brother oversees the Pune outlets, Pritamani continues to guide and visit each brand personally. “Being in the restaurants, facing a guest that’s where I find my happiness. If you empower people, you will be shocked to know what they can hold on.”

The Foreseen Challenges

We started with 12 core team members who’ve been with me since the beginning. When we expanded The Daily to Pune, six of them moved there - a decision that made all the difference.

While many chase rapid growth, I focused on growing steadily, which helped us build a stronger brand with a stable, committed team. Most of my senior and middle management have been with us for years, and that continuity shows in everything we do.

Identifying Locations

For me, it’s all about understanding the consumers, their preferences, spending habits and what concept fits the location. Before opening The Second House in Goa, I spent nearly a year living there and researching every detail.

The site we chose was offbeat, and many advised against it, but we saw its potential. The lower rent allowed us to invest more in design and technology, turning the space into a unique strength rather than a challenge. I believe every restaurant should have its own distinct identity, shaped by its surroundings and audience.

The AI Designed Restaurant

For The Second House, Pritamani reunited with Ayaz Basrai of Busride Design Studio, who had earlier designed The Daily All Day in Mumbai, a decade ago.

Basrai, who has designed and teaches “AI Meets Design” across colleges, turned this project into a real-world example of how artificial intelligence can reshape architecture. The team researched the property’s history by studying who lived there and poring over vintage photo albums from 60–80 years ago. Using AI, they extracted architectural details from old images to precisely recreate elements like pillars and facades from the 1940s.

Even the lighting at The Second House was custom designed through AI, refined with multiple prompts to achieve the perfect look. The team is now developing a light-and-smoke installation, set to launch by January 2026, where warm air will suspend smoke at chest level - an experimental fusion of design, technology, and science that defines The Second House’s futuristic spirit.

Interiors & Ambience

When launching a restaurant or café, it’s crucial to have a clear concept that ties together the brand name, menu, interiors, and consumer experience. A well-defined vision ensures long-term relevance, with interiors playing a key role in drawing audiences.

For example, at Café Lento Goa, the design celebrates nature as we are growing trees inside the space instead of cutting them down. The name Lento, meaning “slow” in Portuguese, reflects the idea of slowing down with nature. The next Café Lento will open in Koregaon Park, Pune, where each outlet will have a unique design interpretation by the designer.

Meanwhile, Tsuki, our Pan-Asian Japanese restaurant in Pune, operates on a solar-powered, self-sustained terrace. Rather than following trends, our goal is to set examples combining creativity, sustainability, and thoughtful design.

Nurture Creativity & Innovation in Staff

Allow them to make mistakes, as long as the mistake is new, correct it. If the mistake happens again, be stern and not mean. Involve them in processes so they will understand about the work. Be open to learning from everyone. Appreciating staffs works.

The Sustainability Factor

Chef Jyoti, Culinary Director tells the team to use the skin of fruits and veggies in various items. For Eg: We are using watermelon skin in cocktails/mocktails. We have a small farm outside The Second House, Goa from where we use veggies and fruits for cooking.

In Goa, where water scarcity is common, we have built small but meaningful water conservation systems at The Second House. We recharge our onsite well with rainwater, use purification processes to ensure sustainability and even created a glasshouse water tank that stores purified rainwater. During shortages, this stored water supports our operations making the restaurant both eco-conscious and self-sufficient.

Dining is Growing

Experiential dining is increasing a lot and that people are shifting more towards dine-in.

“We are more focused on dine-in than deliveries. After Covid, people are coming back to experience the dining, and restaurants are making their mark by ensuring that customers keep coming back. It’s all about giving the customers unique lasting experiences which stays for long run.”

Menu Development for Each Brands

New menu is not trending base for us. At Lento, Chef is planning to re-image Besan Chilla. “We are working on things that give us nostalgia. We want people to enjoy the comfort food in a unique way. We are using AI to push flavor combination that doesn’t come to the Indian minds. And we are trying the combinations to ensure which flavor-combos work."

Customer Loyalty

Don’t let your staff keep changing. If a person feels welcome, they will keep coming and be your regular customer or a loyal customer. Customer retention comes from employee retention.

Message for New Restauranteurs

Do for right reasons. It’s not easy if you aren’t crazy. If you don’t take risk, so you will never know.

Sustainability at The Orchid Hotel isn’t just a practice — it’s part of the luxury ethos. As one of Asia’s first eco-certified hotels, the brand has blended responsible hospitality with refined comfort. From energy-efficient design and solar power usage to sophisticated water recycling and zero-waste initiatives. Even the smallest details — from eco-friendly amenities to sustainable décor — are thoughtfully curated. In an exclusive interview with Restaurant India Ravi Rai, GM, The Orchid Hotel Mumbai talks bout building a world-class hospitality.

With over two decades in hospitality, Ravi’s journey has been shaped by a passion for creating meaningful guest experiences and nurturing strong teams. Starting at the operational level, which gave him a deep understanding of hotel dynamics and the importance of service excellence. Over the years, he has worked with leading hotel brands across India, gaining valuable insights into diverse markets and evolving guest expectations. Leading The Orchid Hotel, Mumbai — India’s first Ecotel-certified five-star hotel — is a proud milestone. “My focus remains on strengthening its legacy of sustainable luxury while driving innovation, guest delight, and a people-first culture,” he shared. Excerpts:

Leading with Empathy, Purpose

For me, leadership is built on integrity, teamwork, and empathy. I believe in leading by example and fostering an environment where every team member feels heard, valued, and inspired to give their best. When people are motivated, exceptional guest experiences follow naturally. My goal is to cultivate openness, innovation, and accountability—guiding a team united by a shared purpose: to deliver outstanding experiences while upholding our commitment to sustainable and responsible hospitality.

People First

I truly believe that our team is the heartbeat of everything we do. Over the years, I’ve learned that a motivated, happy team is what creates memorable guest experiences. I focus on building a culture rooted in trust, mutual respect, and open communication. Every team member is encouraged to take ownership and share ideas — because innovation often comes from the ground up. I make it a point to recognize efforts, celebrate wins, and ensure that everyone feels seen and valued. When people feel connected to a common purpose, the energy and warmth naturally flow through to our guests.

Happy Teams, Happier Guests

Absolutely — a happy team creates happy guests. I keep my team motivated by fostering purpose, pride, and empowerment.

Regular training, recognition, and open communication keep them engaged and confident. When every member feels valued and trusted, they naturally deliver experiences that meet the expectations of today’s well-travelled guests

Experience at the Centre

At The Orchid Hotel, we believe true hospitality lies in the details — in the warmth of our people, the flavours on the plate, and the moments that make guests feel genuinely cared for. Food is at the heart of every experience here — from our award-winning restaurants to our regional dining concepts that celebrate India’s rich culinary heritage. Our team goes beyond service; they create connections with guests through thoughtful gestures and personal touches. Whether it’s remembering a guest’s favourite dish or anticipating their preferences, our focus is always on creating experiences that feel authentic, soulful, and deeply memorable.

Promoting Responsible Tourism

In a city as dynamic and diverse as Mumbai, hospitality has the power to shape how travellers connect with the destination. At The Orchid Hotel, we view our role as curators of responsible tourism — blending the city’s vibrant energy with conscious luxury. Through sustainable operations, locally rooted culinary experiences, and meaningful community initiatives, we aim to offer guests a deeper, more authentic connection to Mumbai. It’s about inspiring travellers to experience the city thoughtfully — celebrating its culture and spirit while treading lightly on its environment.

The Tech-Play

Technology enhances every aspect of our operations and guest experience — from smart check-ins to data-driven personalization and sustainable resource management. Yet, while innovation drives efficiency, it’s our people who bring the warmth, empathy, and authenticity that define every stay.

Authenticity at the Table

Our culinary philosophy is rooted in authenticity, creativity, and a deep respect for ingredients. We take pride in offering distinct dining experiences — from the coastal richness of South of Vindhyas and the global flavours at Boulevard to the open-air charm of Mostly Grills, where gourmet dining meets a relaxed rooftop ambiance. Our chefs focus on fresh, locally sourced produce and craft menus that balance innovation with comfort. What truly sets us apart is the soul we bring to every meal — warm, intuitive service and a genuine passion for hospitality.

Creating a Culinary Landmark

Our restaurants are key to positioning The Orchid Hotel as a true culinary destination. With distinct venues like South of Vindhyas, Mostly Grills, and Boulevard, we attract a strong non-resident crowd. Through curated events, food festivals, and digital outreach, we’ve built each restaurant as a standalone dining experience in Mumbai’s vibrant food scene.

Trends to Watch

Personalised services, Sustainable Luxury, smart technology, local and authentic dining options and warm hospitality.

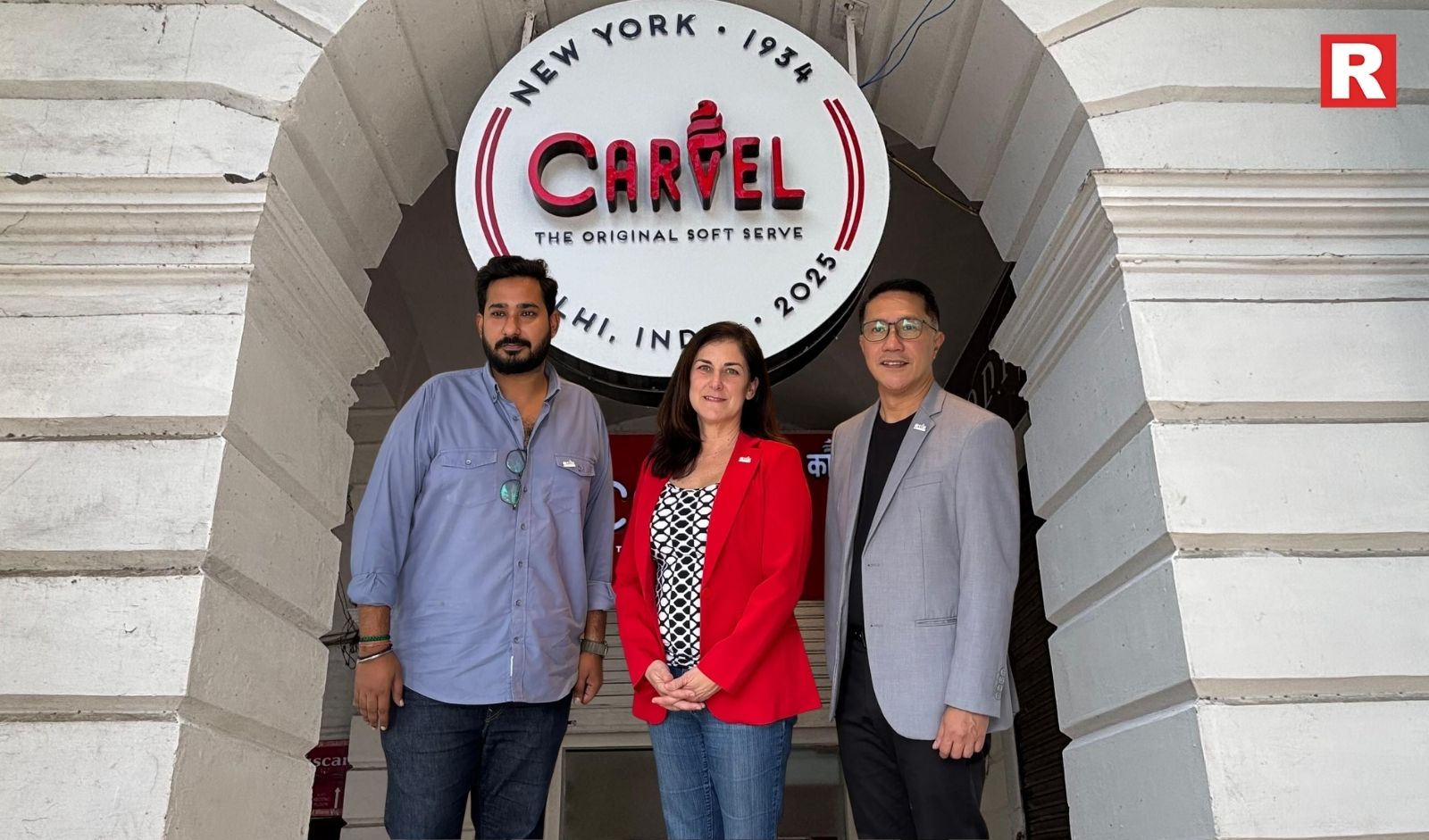

Carvel, the iconic American brand credited as the inventor of soft serve, is making its highly anticipated entry in India. With a Rs 40 crore investment planned over the next five years, the company aims to open 100 stores across key metros and tier-2 cities. But rather than merely replicating its international model, Carvel is taking a carefully localized approach to carve out its space in India’s competitive dessert market.

“In a QSR ice cream business, we need to have the right ratio of localization while still ensuring that the heritage is adapted and executed,” said Sumer Sethi, CEO & Founder at UNIFY Foodworks, who has partnered with the brand for India expansion. Excerpts:

Localisation as Key

The thought process has gone into who the consumer is while still retaining the heritage, international DNA of the brand. In India, if you do not have anything with gulab jamun or Indian filter coffee or a kasata, we felt it was an incomplete offering. This localization strategy comes to life through innovative menu offerings that blend Carvel’s signature soft serve with Indian flavours. Some of the highlights include Indian Filter Coffee Dasha, Kasata Dasha, and a Gulab Jamun Lava Sundae.

Heritage Meets Innovation

India’s quick-service dessert segment has witnessed rapid growth in recent years, with both homegrown and international players vying for market share. Carvel’s strategy hinges on leveraging its heritage, product defensibility, and offline experiential strength. I look at competition in a very positive way. Competition means the category is growing. It’s very difficult to imitate our product. We also saw that there were a lot of B2C brands coming up online, but there were not enough offline players trying to elevate the offline experience. By focusing on physical retail experiences, Carvel aims to stand apart in a market where many dessert brands are heavily digital-led. We are the ones innovating in the offline space where everyone else is innovating on the digital side of things.

Consistency in focus

To maintain consistency across multiple cities, Carvel has invested significantly in supply chain integration and logistics infrastructure. We’ve invested heavily in core logistics, backend integration of supply chain to ensure that this product comes to life in the store with this texture, consistency and price. Human capital is another key pillar. The company aims to create over 1,000 jobs through its store network and has developed digital SOP training modules from the outset. There’s a lot of investment that has gone into creating a digital SOP training module that will be translated into service and the product experience.

Road Ahead

Currently self-funded, Carvel is open to institutional funding as the brand scales. The business would require institutional funding at some point in time. When is that time and what scale will differ from person to person. Right now, we’re self-funded and we’re good to go with that. The brand also plans to build a strong digital presence through heritage-led storytelling and loyalty programs. Carvel’s India entry isn’t just about bringing an American dessert brand to new consumers—it’s about thoughtfully adapting a heritage concept to local preferences while maintaining global standards. By combining flavour innovation, operational discipline, and strategic expansion, Carvel aims to redefine how Indians experience quick-service desserts. With its heritage as its backbone and India’s evolving dessert culture as fertile ground, Carvel seems poised to create a unique niche in the market.

Carvel’s India expansion will focus first on metros like Bengaluru, Hyderabad, Mumbai, and Delhi before entering tier-2 cities. The brand has earmarked Rs 40 crore to set up 100 stores over the next five to six years, signaling a steady and strategic rollout.

Sameer Bhasin is a seasoned hospitality professional with over two decades of experience in the food and beverage industry. As CEO of Nando’s India, he has played a pivotal role in expanding the brand’s footprint across the country, combining global standards with local tastes to drive sustainable growth. In an exclusive interview with Restaurant India, Sameer Bhasin, CEO of Nando’s India, discusses the strategies behind building a strong casual dining brand in India. He emphasizes innovation, customer experience, and localization as key drivers of success in the competitive F&B landscape. Excerpts:

How does Nando’s uniquely position itself between QSR and casual dining in India?

We take pride in leading the flame-grilled peri-peri chicken space — a healthier, spicier alternative that delivers bold, fiery flavor. As an international brand, we’ve built strong consumer loyalty over time by staying true to our no-fluff philosophy: real, high-quality chicken, flame-grilled to perfection, never fried, and packed with 100% protein.

Our offerings come with generous accompaniments, creating a wholesome meal experience that sits just below the casual dining segment in terms of pricing — about 40% more value-efficient when measured by APC. While we don't compete directly with casual dine-in brands, we offer an elevated experience at a significantly lower cost. We’ve also reimagined what QSR means in the Indian market. Today’s consumers are aspirational — they want to move beyond functional food to something more experiential. That’s exactly where we come in. With prices starting just 20–25% above traditional QSR, we guide our customers up the value chain through a thoughtful, experience-led journey.

Customer at the Centre

We’ve invested deeply in understanding our customers. Every restaurant we’ve opened has been shaped by consistent consumer feedback. Over time, we've built a loyal following — guests who return regularly for their Nando’s fix.

But we also asked ourselves: how do we widen the funnel? That led us to a deeper study of the QSR landscape. We recognized that while QSR consumers are value-conscious, they’re also increasingly aspirational. They’re looking for better quality, better experiences — but without the sticker shock that often comes with full-service dining. So, we designed our offering to hit that sweet spot. Take our burgers, for example — they start at around ₹180–₹190. For just 15–20% more than typical QSR pricing, customers get premium flame-grilled food (not fried), a beautiful ambience, and attentive table service — all hallmarks of a more elevated experience.

Menu Designing

Our Indian menu actually offers more variety than the international one — not by regionalizing or altering the core Afro-Portuguese identity of Nando’s, but by thoughtfully curating additions that resonate with the Indian palate. We’ve introduced certain dishes, ensuring they align with local taste preferences without compromising on the brand’s global essence. Take our rice bowls, for instance — the flavor profiles include elements like cashew-based gravies that feel familiar to Indian consumers, yet the foundation remains Afro-Portuguese. This approach allows us to stay true to Nando’s heritage while offering something that feels both exciting and approachable. Indian diners are incredibly discerning when it comes to food — they’re deeply attentive to flavour, quality, and authenticity. That’s worked to our advantage.

Health on the Card

Another growing trend we’ve tapped into is the increasing focus on protein-rich diets in India. Our flame-grilled, protein-forward offerings have found strong appeal among health-conscious consumers looking for meals that are both nutritious and full of flavour. It’s become a strong driver of repeat visits. We’ve seen a noticeable affinity from health-conscious consumers, particularly in locations near gyms and fitness hubs, where gym-goers regularly choose Nando’s as their go-to post-workout meal. It’s not just about great taste — it’s about food that fits their lifestyle, and that connection is strengthening our brand’s appeal within this evolving segment.